NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

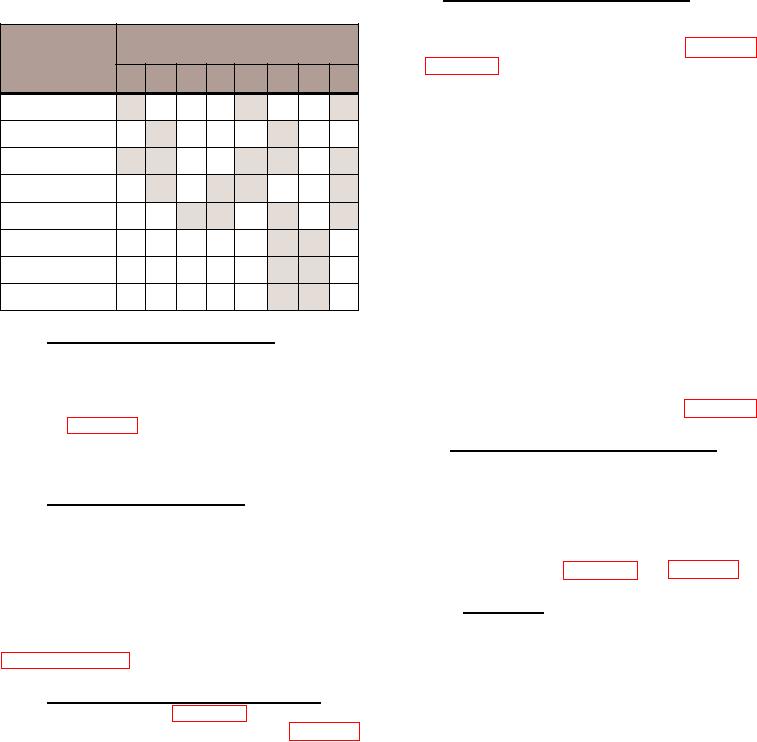

2-4.9. C L E A N I N G TRACK EXAMPLE. As an

Types of Contamination versus

illustrative example of cleaning track use, assume the

Cleaning Tracks

cleaning track is "BCSR235". This would correspond

Cleaning Track Numbers

to the following maintenance actions (refer to Figure 2-3

Type of

and Table 2-3):

1

2

3

4

5

6

7

8

a. B - Clean with the abrasive tool and glass beads.

√

√

√

Light Dirt/Dust

√

√

Heavy Dirt/Dust

b. C - Scrub with cleaning brush.

√

√

√

√

√

Salt Spray

c. S - Clean with water base spray with one ounce

√

√

√

√

Light Corrosion

of detergent, MIL-D-16791, in 1 gallon of fresh water at

a maximum of 30 psi.

√

√

√

√

Heavy Corrosion

√

√

Oil

d. R - Rinse with water base spray with fresh water

at a maximum of 30 psi.

√

√

Grease

√

√

Hydraulic Fluid

e. 2 - Dry in circulating air drying oven at 130F

(54C).

2-4.6. TYPE OF AVIONIC EQUIPMENT. The criteria

f. 3 - Air dry as required.

for selection of a cleaning track are also based on type

of avionic component to be cleaned. A thorough

g. 5 - Preserve as specified by the component's

inspection of the item to be cleaned is important to

Maintenance Instruction Manuals (MIMs) or Chapter 9.

determine the type of circuitry and components

involved. Table 2-2 is a guide for determining the

2-4.10. CLEANING TRACK DESCRIPTIONS. The

cleaning track to use on various electronic and electrical

components.

cleaning tracks are designed to fulfill specific functions.

Drying selection depends on availability of drying

2-4.7. CLEANING RESTRICTIONS.

ovens, Volume of the component, and time available

for drying. Appropriate painting, preservation, and

2-4.7.1. Selection of the cleaning track is a decision to

packaging steps are selected for the individual item

be made by the avionic cleaning facility supervisor.

being cleaned. The following are description of each

Certain circuit components can be damaged by support

cleaning track based on Figure 2-3 and Table 2-3.

equipment.

2-4.10.1. Track No. 1.

2-4.7.2. The use of support equipment on certain

avionic equipment and components is restricted

2-4.10.1.1. This track removes light dirt, dust, and

(paragraphs 2-5.2. to 2-5.2.5.3.).

salt spray. Solvent and detergent ultrasonic cleaners

are not required. This track is considered the mildest

2-4.8. CLEANING TRACK IDENTIFICATION. The

and has the widest application in cleaning of various

Cleaning Track Diagram, Figure 2-3, shall be used in

types of avionic equipment.

conjunction with Cleaning Track Legend, Table 2-3.

The cleaning track legend defines each element of the

2-4.10.1.2. The component is cleaned and rinsed in

cleaning track. Each function and subfunction on the

the Cleaning Booth (Booth, Cleaning, Water Base

cleaning track is assigned an alphanumeric code.

Solvent Spray) using Detergent, MIL-D-16791. One

These characters are used to identify the cleaning

ounce (2 tablespoons) of detergent is mixed in one

track for recordkeeping purposes. It may be desirable

gallon of fresh water.

to keep a log of all avionic equipment and components

processed through the cleaning tracks. In such cases,

the cleaning track number would identify exactly the

process used when cleaning a particular component.