NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

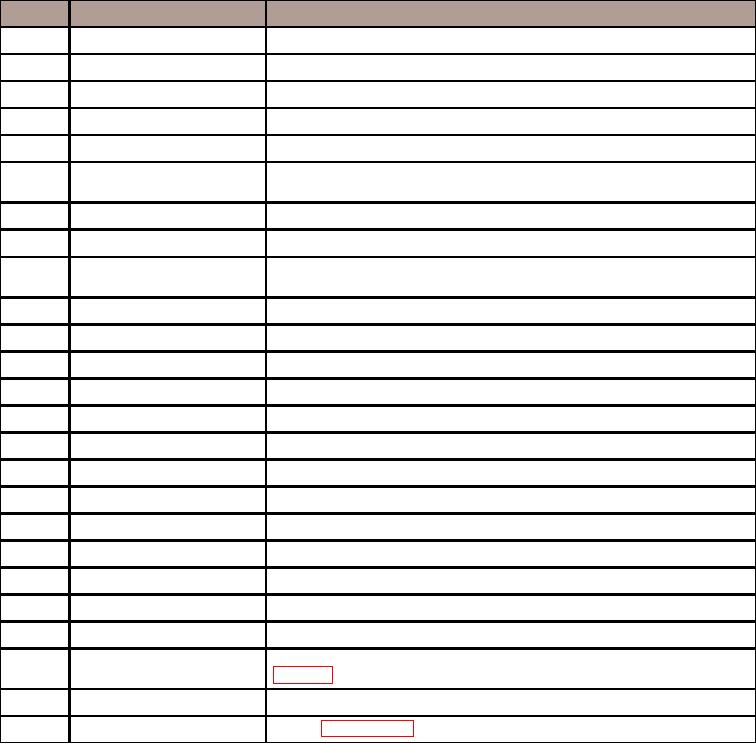

Table 2-3. Cleaning Track Legend

Code

Equipment

Notes

B

Abrasive Tool

Glass Beads, MIL-G-9954

C

Scrub

Cleaning Brush, A-A-2074

S

Water Base Spray Clean

Detergent, MIL-D-16791, at 30 psi maximum

R

Water Base Spray Rinse

Fresh Water Rinse at 30 psi maximum

W

Mini-Abrasive Unit

Sodium Bicarbonate, Technical, A-A-374

Ultrasonic Detergent Presoak

1 ounce (2 tablespoons) Detergent, MIL-D-16791, to 1 gallon of water at 30 psi

P

at 130 F (54 C)

PA

Ultrasonic Detergent Presoak

30 seconds

PB

Ultrasonic Detergent Presoak

60 minutes

Ultrasonic Detergent Clean

1 ounce (2 tablespoons) Detergent, MIL-D-16791, to 1 gallon of water at 30 psi

D

at 130 F (54 C)

DA

Ultrasonic Detergent Clean

30 seconds

DB

Ultrasonic Detergent Clean

3 minutes

DC

Ultrasonic Detergent Clean

15 minutes

1

Forced Air Drying Oven

130 F (54 C) maximum

1A

Forced Air Drying Oven

30 minutes

1B

Forced Air Drying Oven

1 hour

1C

Forced Air Drying Oven

2 hours

2

Circulating-Air Drying Oven

130 F (54 C) maximum

2A

Circulating-Air Drying Oven

4 hours

2B

Circulating-Air Drying Oven

8 hours

2C

Circulating-Air Drying Oven

16 hours

3

Air Drying

As required

4

Paint

Refer to Volume II (Navy), TO 1-1-8 (Air Force), or TM 55-1500-345-23 (Army)

Preservation

Refer to preservation procedures as specified for component's MIMs or

5

6

Refer to NAVAIR 01-1A-23 (Navy) or TO 00-25-234 (Air Force)

7

Packaging

Refer to paragraph 9-3.