TM 10-3510-220-24

2-40. WATER MANIFOLD ASSEMBLY (CONT)

ADJUSTMENT

NOTE

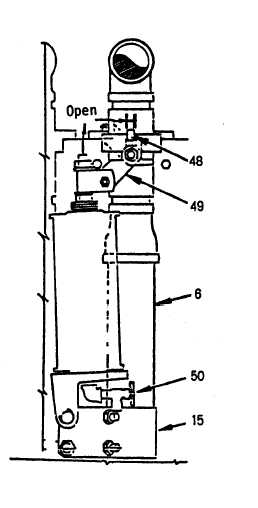

Ball valve crank (49) and anchor bracket (15)

must be exactly in line. The air actuator must

not be slanted or cocked with relation to the

plane of crank move-merit. Binding between

the crank and anchor bracket will occur if

they are misaligned.

1. Check clearance after piping the machine.

Maintain 1/16” ± 1/32” clearance between the open

and closed crank stop (48) positions to prevent valve

stem damage when closed and ball overtravel when

opened.

NOTE

Overtravel will cause the valve to throttle the

flow of incoming water. This has a

detrimental effect on valve life and also

increases filling time.

2. To adjust both the alignment and clearance,

loosen the anchor bracket (15) and perform the

following as needed:

a. Rotate the anchor bracket (15) around the pipe

(6) to adjust alignment.

b. Slide the anchor bracket (15) up or down the

pipe (6) to adjust clearance.

3. Adjust the needle valve (50) (if equipped) to

slow the opening and closing of the air actuated ball

valve assembly. One quarter to one half turn is

normal.

4. Ensure that all air actuated ball valve

assemblies close at the same speed.

2-142