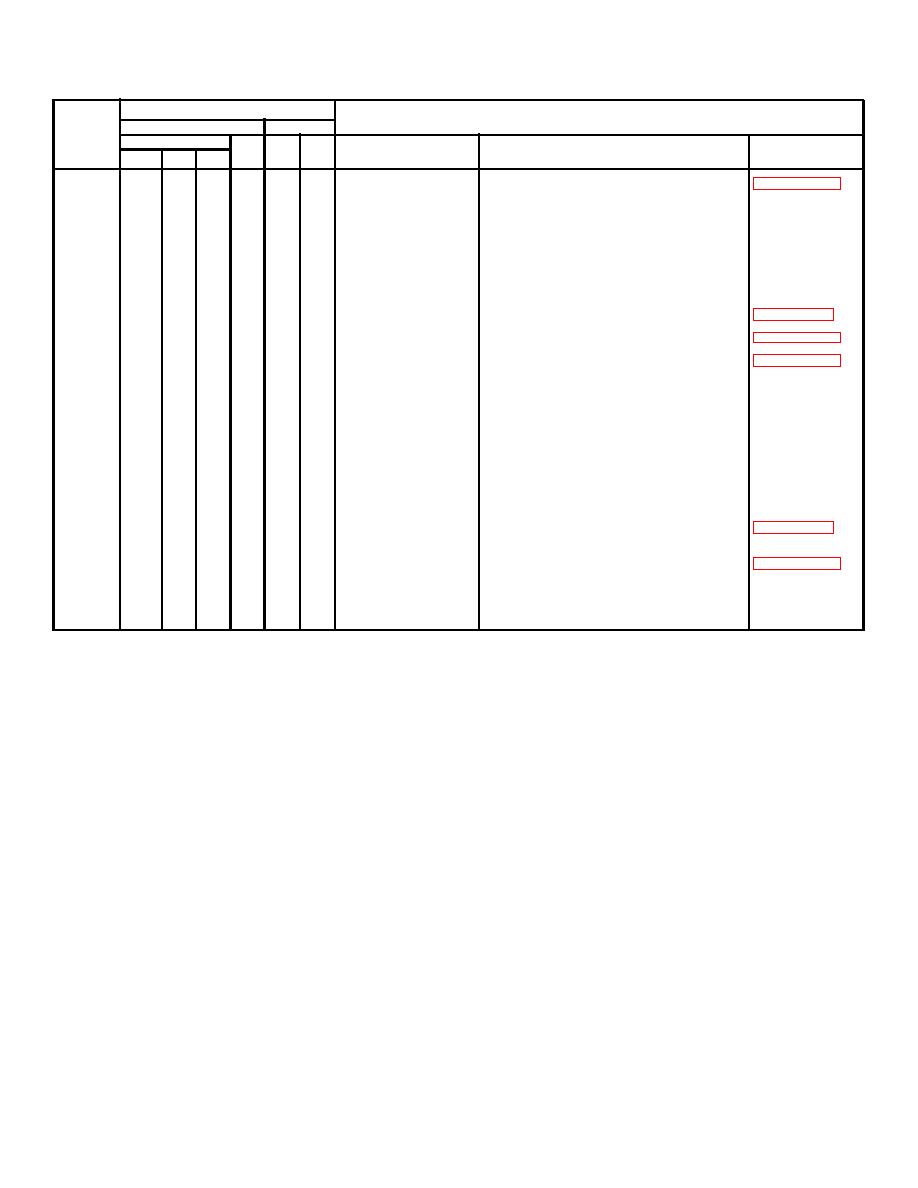

TM 10-4510-201-14

Interval

B - Before operation

A - After operation

M - Monthly

Item

Operator

Org.

D - During operation

W - Weekly

Q - Quarterly

Number

Daily

B

D

A

W

M

Q

Item to be inspected

Procedure

Reference

1

X

X

Water line strainer

Inspect for dirty, broken and leaking strainer.

2

X

X

X

Sight tube glass

Inspect for dirty and broken glass.

3

X

X

X

Burner -nozzle and

Inspect nozzle and electrode holder for loose

electrode holder

mounting. Inspect lead assemblies for loose

connections. Check firebox for improper

combustion, and electrode for improper

spark (during operation).

4

X

X

X

Fuel line and hose

Check for loose connections and for broken,

assemblies

bent, and leaking line and hose assemblies.

5

X

X

Fuel drum

Check level of fuel supply and check for leaks

in drum.

6

X

X

X

Water hose

Check for cracked, collapsed, and leaking

assemblies

hoses, and for loose connections.

7

X

X

Shower head

Inspect for dirty and clogged nozzles.

nozzles

8

X

X

Instruments

Check for broken lenses, illegible markings,

and loose connections. Check for incorrect

temperature and for pressure that is too high

or too low (during operation).

9

X

X

Drain plugs and

Check for improper installation of drain plugs

drain cocks

and drain cocks.

10

X

X

Fuel filter

Check for leaking and dirty filter. Hand lever

must be turned one complete turn daily.

11

X

X

Exhaust duct

Inspect for broken, dirty, and leaking duct and

for loose connections. Be sure the duct is not

clogged or does not contain any flammable

litter.

12

X

Power cord cables

Check for loose or broken connections and for

cracked and deteriorated insulation.

13

X

X

X

Suction strainer

Inspect for dirty and clogged strainer. Check

for improper positioning of strainer (during

operation).

14

X

Fire extinguisher

Inspect for broken seal.

15

X

X

X

Water heater

Check for water leaks.

Note 1. Ground

Before operation, make sure generator set is

terminal

properly grounded.

Note 2. Opera-

During operation, observe for excessive

tional test

vibration and noisy motors.

3-2