Section IV. TROUBLESHOOTING

4-11. General

For a general description and purpose

of

the

The troubleshooting table (table 4-2) is as follows:

troubleshooting table, refer to paragraph 3-3.

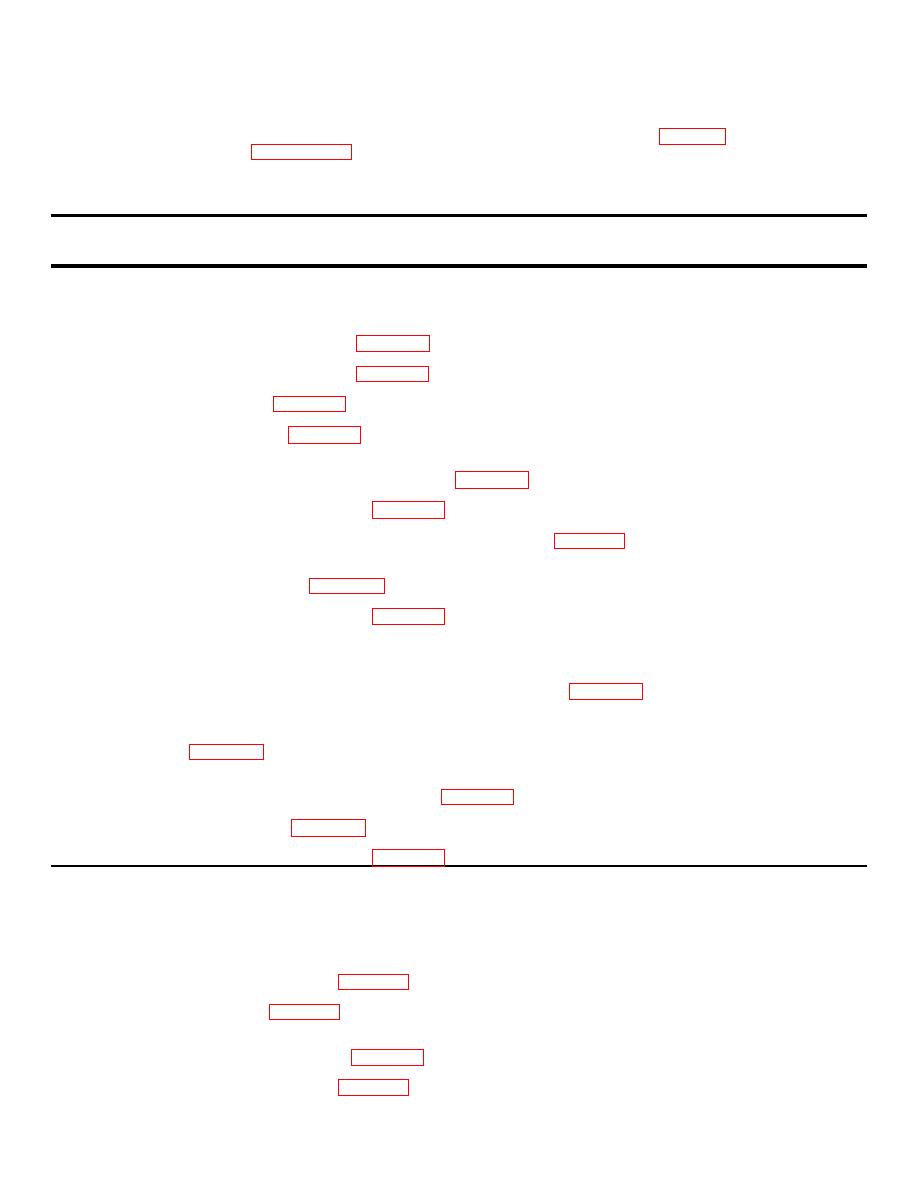

Table 4-2. Troubleshooting

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

SHOWER STAND AND WATER PUMP ASSEMBLY

1. SHOWER STAND NOZZLES NOT DISCHARGING ENOUGH WATER

Step 1. Check to see if water pump is worn excessively.

Install serviceable pump (para 4-26).

Step 2. Inspect for broken shower stand control valve.

Install serviceable valve (para 4-21).

Step 3. Check for leaking hose.

Repair hose (para 4-16).

Step 4. Check for clogged water line strainer.

Clean strainer (para 4-23).

2. WATER PUMP FAILS TO DELIVER WATER

Step 1. Inspect for clogged impeller.

Remove pump body and clean impeller (para 4-26).

Step 2. Check for damaged impeller.

Install serviceable impeller (para 4-26).

Step 3. Check for reverse rotation.

Interchange any two of the external leads at the motor (para 4-25 d ).

3. WATER PUMP FAILS TO DEVELOP ENOUGH PRESSURE

Step 1. Inspect for leaking shaft seals.

Replace the seals (para 4-26e ).

Step 2. Inspect for broken impeller.

Install serviceable impeller (para 4-26).

4. WATER PUMP FAILS TO ROTATE

Step 1. Check for dirty or clogged impeller.

Clean impeller.

Step 2. Check to see if electric motor is operating.

Check electrical connections or install serviceable motor (para 4-25).

5. PULSATING PRESSURE ON WATER DISCHARGING FROM SHOWER STANDS

Step 1. Check for excessively worn pump.

Check pump prime. If pump will not stay primed install serviceable pump

6. WATER PUMP NOISY

Step 1. Check for excessively worn motor bearings.

Install serviceable water pump motor (para 4-26).

Step 2. Check for dirty impeller.

Clean impeller (para 4-26d).

Step 3. Check for excessively worn or broken impeller.

Install serviceable impeller (para 4-26).

WATER HEATER ASSEMBLY

1. FUEL PRESSURE TOO LOW ON GAGE

Step 1. Check for excessively worn burner control valve.

Install serviceable valve (para 4-401).

Step 2. Check fuel pump for proper adjustment.

Adjust pump pressure (para 4-41a (5)).

Step 3. Check for dirty or clogged fuel filter.

Clean filter (para 4-41c ).

2. FUEL PRESSURE TOO HIGH ON GAGE

Step 1. Check for defective pressure gage.

Install serviceable gage (para 4-40j).

Step 2. Check fuel pump for proper adjustment.

Adjust pump pressure (para 4-41a (5)).