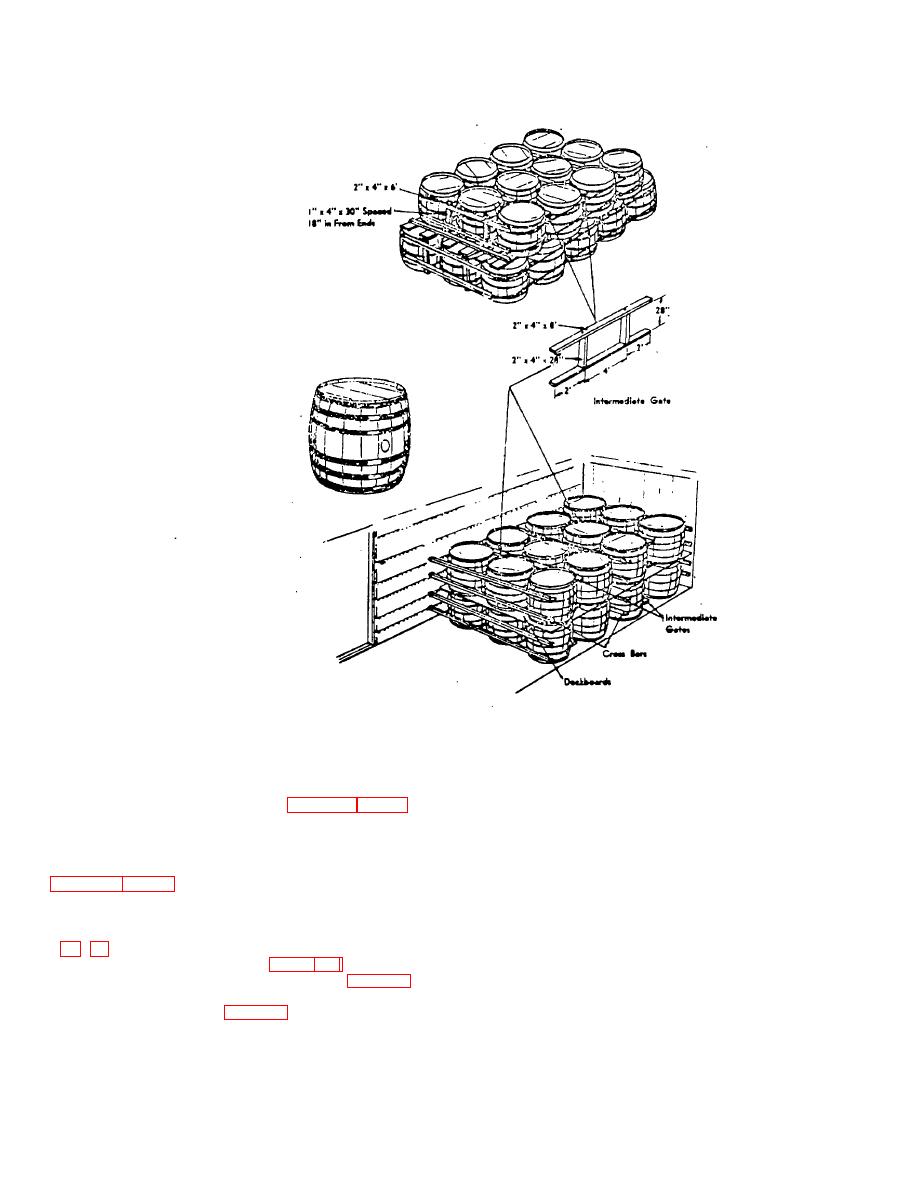

Figure 47. Tierces double-decked floating load.

Figure 48. Tierces loaded in equipped cars.

(7)

In each loading plan, the drums must be loaded

(6) The best method for loading fiberboard drums

tightly throughout the car and be forced back into place.

is by the nested pattern, as shown in figures 52 and 53. The

Drums in all stacks must be offset, as shown in the figures, in

number of drums in the first loaded stack will depend on the

order to maintain two-point contact with adjacent drums.

diameter of the drums and the width of the car. The

Each stack should be in alignment across the car so that the

maximum number of drums possible should be loaded in the

last stacks of the load in the doorway have a "square front" for

first stack to obtain the most desirable offset pattern shown in

proper application of bracing.

the first stack as illustrated.

(8) It is strongly recommended that only full or

Variations in sizes of drums may result in patterns of 434, 6-

complete layers of drums be loaded. A full or complete layer

referred to here is a layer from the end walls of the car to the

wide across the car as shown in figure 52, then load the

doorway area bracing. If an incomplete layer of drums is

drums in the 43-4 nested pattern as shown in . figure 53. An

loaded, filler material must be placed between the full and

alternate to this would be the 4-4 ) (equal number) offset

incomplete layers. Filler decking is important to maintain

loading pattern, as shown in figure 54.

alignment and stability of the drums in multi-layer loads and

may be of

29