TM 10-3510-209-24

Table 2-2. Unit Troubleshooting (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

32.

AIR PRESSURE IS TOO LOW (BELOW 60 PSI [414 kPa]) or TOO HIGH (ABOVE 80 PSI

[552 kPa]). (Cont)

Step 4.

Check for broken pressure switch. Temporarily substitute a known

good switch for the suspect switch.

a.

If switch is defective, replace pressure switch. Refer to

paragraph 2-24.

b.

If switch is serviceable and problem persists, notify your

supervisor.

WASHER ASSEMBLY

33.

WASHER WILL NOT FILL AND CYLINDER WILL NOT ROTATE.

Step 1.

Check for improperly adjusted door safety switch. Door should be

secured and watertight just as the switch is activated.

a.

If switch is improperly adjusted, adjust safety switch. Refer

to paragraph 2-20.

b.

If switch is serviceable, proceed to next step.

Step 2.

Check for failure of door safety switch. Perform continuity check

with power off.

a.

If door safety switch is defective, replace switch.

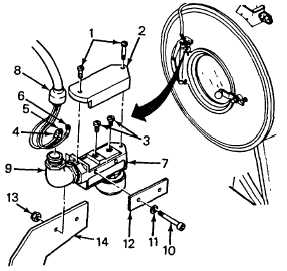

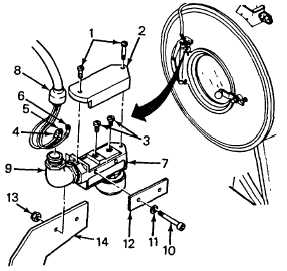

(1) Remove two screws

(1) and switch top

(2).

(2) Tag and disconnect

wire (4) from switch

top (2).

(3) Remove two screws

(3). Tag and dis-

connect wire (5) and

(6) from switch (7).

(4) Remove conduit nut

(8) at elbow (9) and

remove wires from

housing of switch

(7).

(5) Remove two allen head screws (10), lockwashers (11), plate

(12), two nuts (13), and switch (7) from mounting bracket

(14).

2-49