TM 10-3510-209-24

2-21.1. WASHER FLOAT LEVEL ASSEMBLY

This task covers:

a. Inspection

c. Disassembly

e. Installation

b. Removal

d. Repair

f. Adjustment

INITIAL SETUP

Tools

General Safety Instructions

General mechanic's tool set,

SC 5180-90

WARNING

High voltage is present on this equipment. Do not perform

Personnel Required

maintenance with power on. Death or serious injury may result.

MOS 63J (1)

Equipment Conditions

Materials/Parts

TM 10-3510-209-10, Water drained from washer.

TM 5-6115-585-12, Generator off.

TM 10-3510-209-10, Water pump removed.

Paragraph 2-22, Washer drivebelt cover removed.

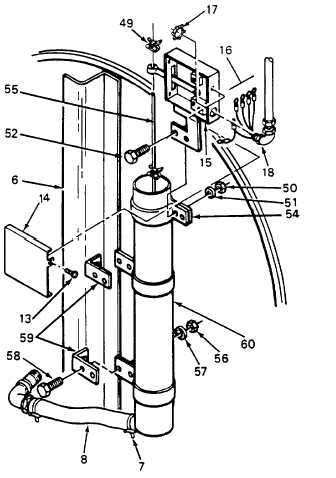

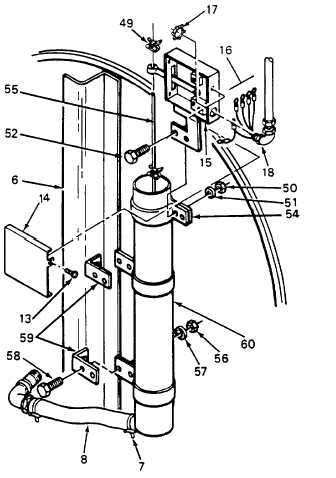

INSPECTION

Inspect for cracks, freeze breaks, loose fittings,

damaged hose or incorrect float operation.

REMOVAL

a.

Remove screw (13) and cover (14) from

float switch (15).

2.

Tag and disconnect wires (16) and remove nut

(17) from electrical cable (18). Remove electrical cable

from float switch (15).

3.

Loosen clamp (7) to remove tube (8) from float

chamber (60).

4.

Remove four bolts (58), nuts (56) and washers

(57) from support brackets (59).

5.

Remove float chamber (60) from washer

assembly (6).

DISASSEMBLY

1. Remove low-level speednut (49) from float rod

(55) by pinching speednut ends together.

2.

Remove hex nut (50), lock washer (51) and

screw (52) from float switch assembly (15) and float

chamber clamp (54).

3.

Remove float switch assembly (15) from float

rod (55).

4.

Remove float rod (55) from float chamber (60).

2-84 Change 1